MATERIALS

AirBeam

A creative technological solution to setting up temporary structures using compressed air. CLICK FOR MORE.

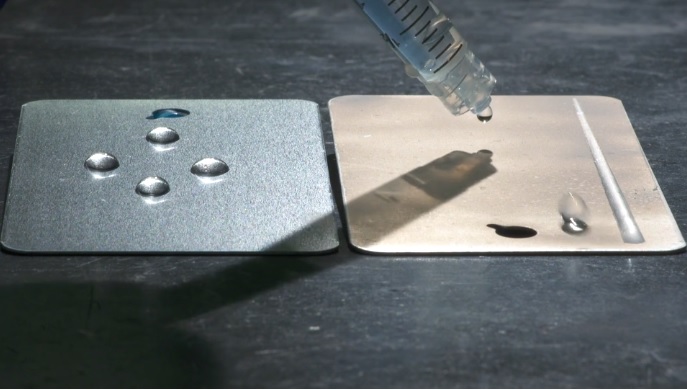

NBD Nano- A Water Repellent Friction Free Technology

An Air Force funded technology that has water repellant applications in the automotive, construction and clothing industries CLICK FOR MORE.

TCP: An Environmentally Safe Corrosion Treatment

The US Navy has developed an environmentally friendly coating against corrosion for aluminum alloys CLICK FOR MORE.

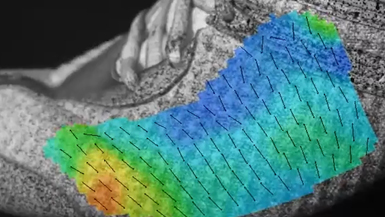

Trilion - High Resolution Digital Camera Strain Measurement

A small materials research company in Cincinnati, Ohio, answered a call from the U.S. Air Force in the early 2000s and today finds itself immersed in a revolutionary transition in manufacturing. CLICK FOR MORE.

BTG Labs- The Surface Analyst

A small materials research company in Cincinnati, Ohio, answered a call from the U.S. Air Force in the early 2000s and today finds itself immersed in a revolutionary transition in manufacturing. CLICK FOR MORE.

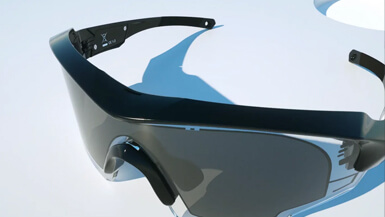

AlphaMicron: A Liquid Crystal Technology That Can Change Light Levels Instantaneously

Concern about reliable visibility of helmet-mounted displays led to a revolutionary light-attenuating liquid crystal technology. CLICK FOR MORE.

FlexSys

After a century of trying they have figured out how to change the shape of aircraft wings in flight, like birds can do. CLICK FOR MORE.

NAVSOLVE™

NAVSOLVE™ is an environmentally friendly "green solvent" used to clean grease and hydraulic fluids. Naval Air Warfare Center Aircraft Division, Maryland CLICK FOR MORE.

Digital Opacity Method

A new plume opacity measurement technology known as Digital Optical Method (DOMTM). DOMTM estimates the opacity of plumes in the out door ambient environment by analyzing digital images that are produced by off-the-shelf digital cameras. CLICK FOR MORE.

High Performance Composite Metal Foam

A lightweight high strength metal foam eight times stronger than bulk steel NC State University

Wake Forest University CLICK FOR MORE.

Fire Resistant Core Materials- Ecore

A core material made from fly ash, which is lighter, stronger and more fire resistant NCA&T Greensboro,NC CLICK FOR MORE.

Cryogenics Laboratory

Kennedy Space Center seeks partners to take advantage of our Cryogenics Test Laboratory. The Cryogenics Test Laboratory houses one-of-a kind capabilities for research, development, and application of crosscutting technologies to meet the needs of a wide variety of customers.

Kennedy Space Center FL CLICK FOR MORE.

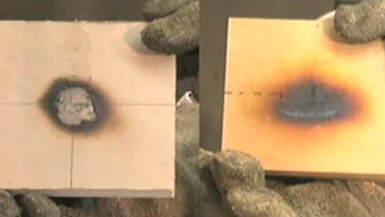

Elastomeric Blast Protection

Protection against blast and ballistic damage is improved by encapsulating or sandwiching rigid inclusions (for example, tiles) or a rigid plate by a high-strain rate hardening elastomer. Typical high-strain rate hardening elastomers include polyurea and polyurethane. NAVSEA, Carderock CLICK FOR MORE.